Fuel Injection Pumps Dave's Diesel

2] Metering of the fuel: The inline fuel injector pump helps to control the amount of fuel to be supplied to the injector. 3] Distribution of fuel: This is another important function of the fuel injection pump, to distribute the fuel to all the injectors at the exact time.

Sell Bosch Inline Fuel Injection Pump in Chicago Heights, Illinois, US, for US 1,000.00

Mounting tool set for mounting of element seal on inline injection pumps of size P 8000/8500, R. See on catalog. ref. 0 986 612 495 KDEP 1888. 9985. Puller device (5-piece) for the drive-side bearing cover of the pump body for repair of in-line fuel injection pumps with end face flange mounting, series

Ford 3400, 3500, 4500 Backhoe / Tractor Inline Fuel Injection Pump Rebuilt C5NE9A543K

The JEGS inline fuel pumps are designed to meet your engine's demands. The external mounting is ideal when using fuel cells, drop-sump style tanks, or when it is not practical to use an in-tank unit. Available for both automotive and marine applications. Filter Results Automotive JEGS 159076 Part Number: 555-159076 High Volume Inline Fuel Pump

.jpg)

Universal 12V In Line High Pressure Fuel Injection Pump Replaces 0580464013 eBay

Another type of fuel injection pump is the inline fuel injection pump. This pump design incorporates a single pump element that is positioned in-line with the fuel delivery system. The pump draws fuel from the tank and pressurizes it before delivering it to the injectors. Inline pumps are known for their durability and efficiency, and are.

Hypermax Product Display

An inline injection pump is a type of fuel pump commonly used in diesel engines. It is responsible for delivering fuel to the injectors at high pressure, allowing for efficient combustion. Unlike electric fuel pumps, inline injection pumps are mechanically driven by the engine's camshaft or crankshaft. The operation of an inline injection.

0900007160DR (PES4A700) Rebuilt Inline Injection Pump fits NipponDenso 3L0056 Engine Goldfarb

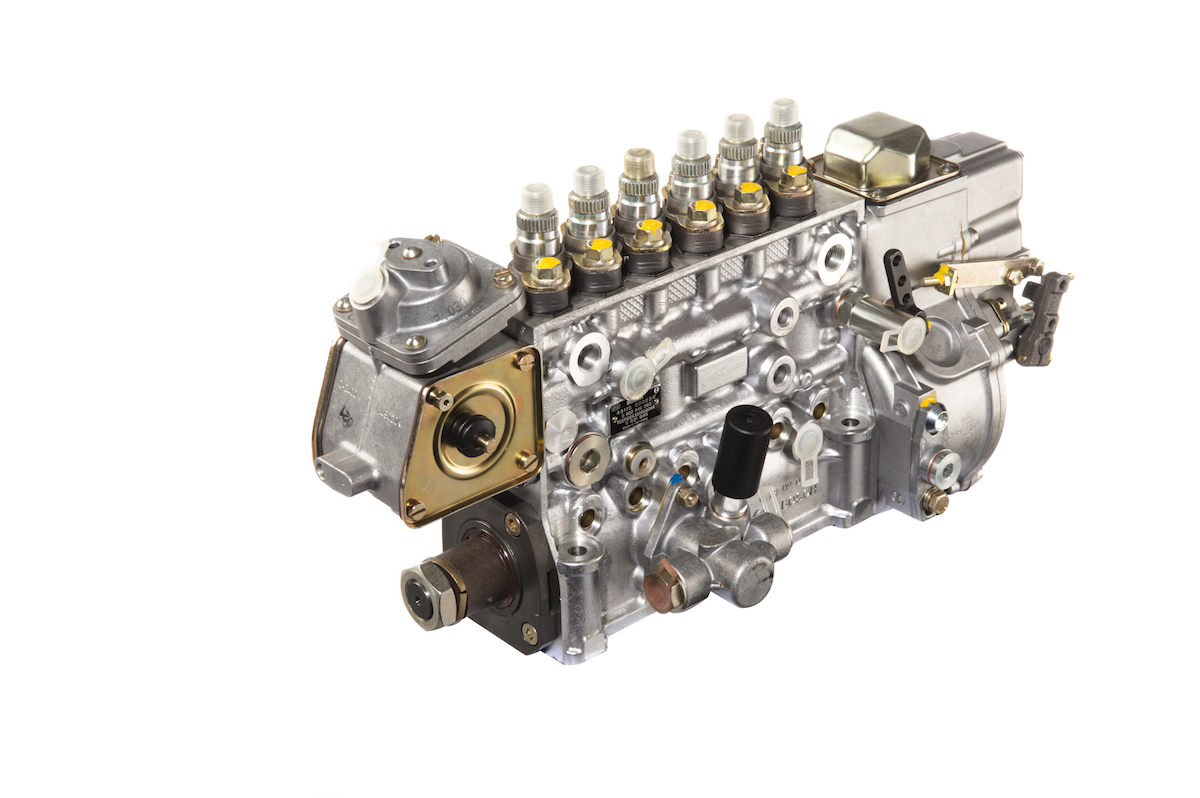

Inline injection pumps look like mini inline engines. The earliest inline injection pumps delivered 3,000-5,000 psi of injection pressure, while the newer Bosch P7100, found on '94.

Ford Tractor Inline Fuel Injection Pump Rebuilt 5000, 5600, 6600, 5610, 6610, 7600, 7700, 6700

http://www.mekanizmalar.com/menu_pump.htmlThis is a video of flash animation of in-line injector pump. Volume of fuel going to injector is controlled by this.

Tebru Fuel Injection Pump, 0580464038, High Pressure Electric Inline Fuel Pump with Installation

Definition of Inline Injection Pump. Inline injection pump is a high pressure pump on a diesel engine that is used to increase diesel fuel pressure up to 18,000 PSI individually. That is, each injector will be served by a plunger unit. It can be said, in a 4 cylinder diesel engine there are 4 injectors and 4 plungers.

In Line & Rotary Injection Pumps

Inline Fuel Injection Pumps In 1927 Robert Bosch produced the first practical diesel pump. This design enabled the newly developed diesel engine to become a viable engine for many applications. The method of fuel metering on this initial pump was port and helix, (high-pressure metering).

How to inline fuel pump fuel setting 13b inline diesel pump fuel injection pump YouTube

Installation Make certain that the engine is rotated to cylinder Number 1 at top dead center. Remove the access plug on the injection pump. A rebuilt or repaired injection pump should be locked in time, with the timing pin engaged. Remove the timing pin.

How to get Engine Firing Order using Inline Injection Pump YouTube

As the name implies, a fuel injection pump is a device in an automobile that pumps fuel into the cylinders of a gasoline or diesel engine. The injection pump is driven indirectly from the crankshaft by a gear, chain, or timing belt, which also operates the camshaft. It is usually attached to the camshaft so that they are interconnected.

Inline Injection Pump Transfer Pumps PCM

[24] 4.4 Inline Injection System An Injection Pump is the device that pumps diesel (as the fuel) into the cylinders of a diesel engine. Traditionally, the injection pump is driven indirectly from the crankshaft by gears, chains or a toothed belt (often the timing belt) that also drives the camshaft.

Bosch Inline Pump Feather Diesel Services Diesel Pump & Fuel Injector specialists

1. Individual inline pump An individual pump is a pump mechanism with an individual fuel delivery system. That means that each injector will be served by a plunger mechanism. It can be say, the number of plungers is the same as the number of injectors. However, all the plungers are placed together in one pump unit in a line position.

Injection Pump with 6 Inline Cylinders and Centrifugal Governor NADA Scientific YouTube

Diesel Engine In-Line Injection System This example shows an in-line multi-element diesel injection system. It contains a cam shaft, lift pump, 4 in-line injector pumps, and 4 injectors. Model Injection System Description The diesel injection system simulated by this model is shown in the schematic diagram below. Figure 1.

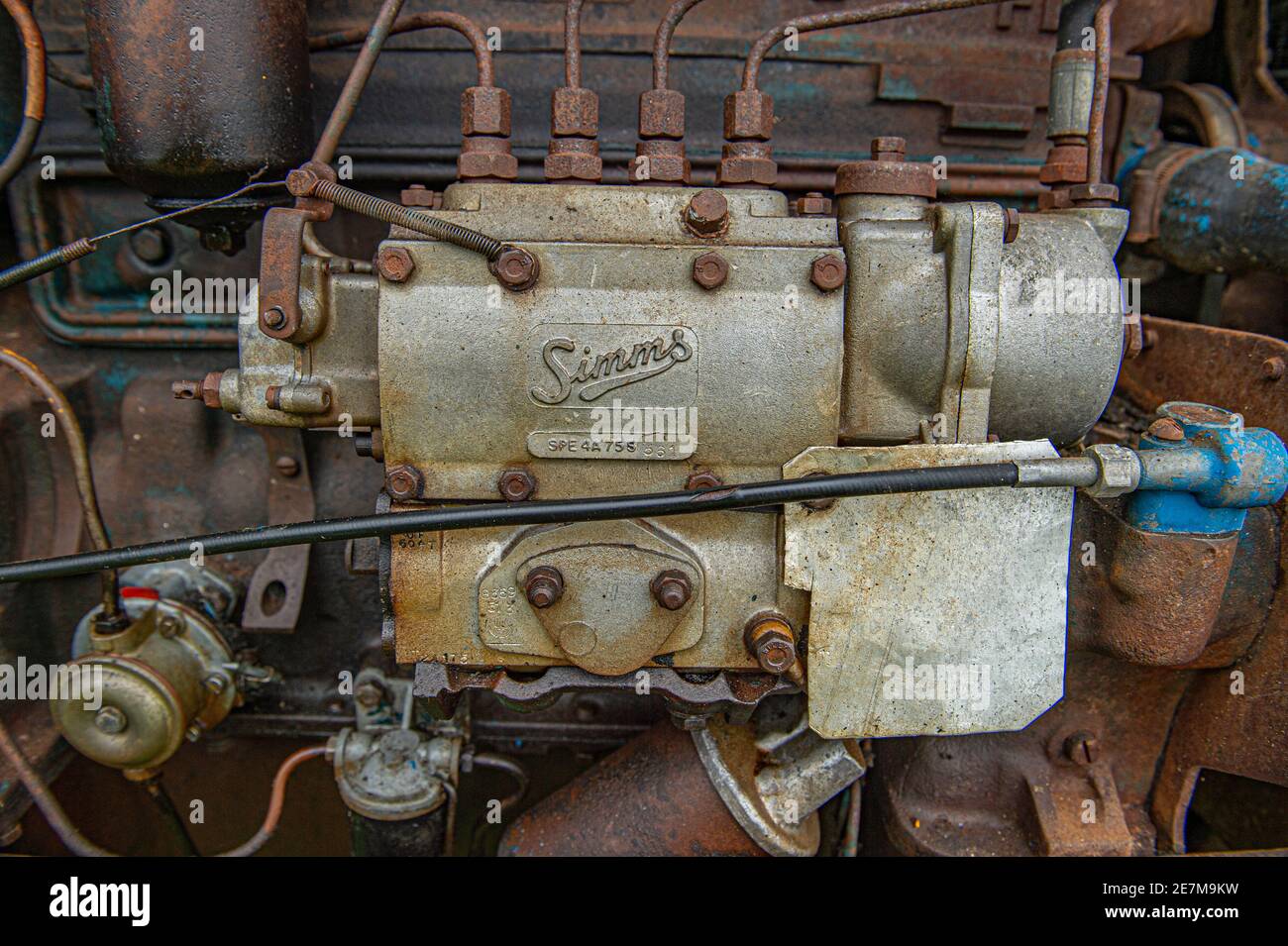

Grey Fergy T20 CAV Inline Diesel Pump

Inline fuel injection pumps, as the name suggests, are arranged in a line with the engine cylinders. Each pump element aligns with its respective cylinder, allowing the pump to deliver fuel directly to that cylinder at the right moment. Inline pumps are well-regarded for their simplicity and reliability. They are predominantly used in larger.

Simms inline diesel injection pump Stock Photo Alamy

Design and construction. The standard PE in-line injection pumps incorporate their own camshaft, and a plunger-and-barrel assembly (pumping element) for each engine cylinder (Fig. 1). The injection nozzles. The injection pump's camshaft is driven by the diesel engine. Injection-pump speed and crankshaft speed are identical for 2-stroke engines.